Extrusion can be classified in several ways. Based on the metal's temperature during extrusion, it is categorized into hot extrusion and cold extrusion. Based on the billet, it can be divided into ingot extrusion, billet extrusion, powder extrusion, and liquid metal extrusion. According to the type of metal, it can be divided into ferrous metal extrusion and non-ferrous metal extrusion. Based on the metal flow direction, it includes forward extrusion, backward extrusion, and lateral extrusion.

1.Classification by Metal Flow Direction

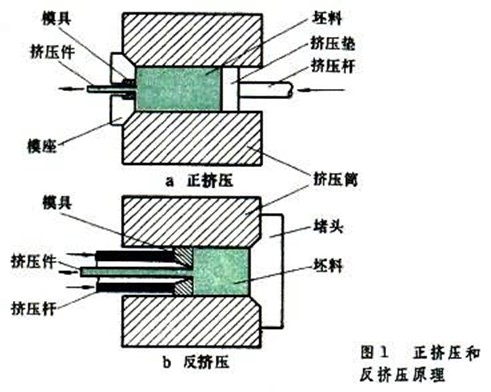

Forward and backward extrusion are classified based on the metal's flow direction, which is the most common method of classification.

- Forward Extrusion

The metal flows in the same direction as the movement of the extrusion ram. During extrusion, there is relative sliding between the metal billet and the inner wall of the extrusion container, resulting in significant external friction, thus requiring higher extrusion force.

- Backward Extrusion

The metal flows in the opposite direction to the extrusion ram. Since there is no relative movement between the metal billet and the extrusion container, there is no external friction.

Forward Extrusion and Backward Extrusion

Backward extrusion requires less force than forward extrusion and results in less metal waste.

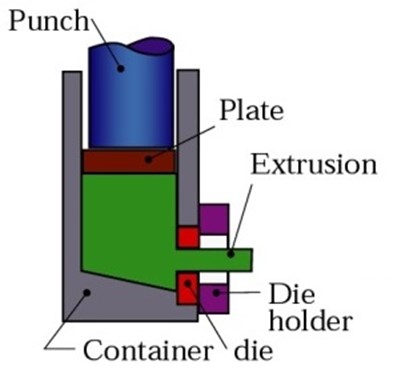

- Lateral Extrusion

In lateral extrusion, the mold and the metal billet axis are placed at a 90° angle. The force applied to the billet aligns with its axis, and the extruded product flows out from the die hole in a direction that is 90° to the extrusion force. Lateral extrusion results in products with minimal longitudinal performance differences and improved material properties.

Lateral Extrusion

2.Classification by Metal Type

Based on the type of metal being extruded, extrusion is classified into ferrous and non-ferrous metal extrusion, with non-ferrous metal extrusion being the most widely used. Non-ferrous metal extrusion can be further categorized into:

- Light Non-ferrous Metals: Includes aluminum, aluminum alloys, and magnesium alloys used to produce extruded products like architectural profiles, wire rods, and tubes.

- Heavy Non-ferrous Metals: Includes lead, copper, zinc, nickel, with copper and copper alloys being the most common.

- Rare and Precious Metals: Includes metals like titanium alloys, tungsten, molybdenum, tantalum, and niobium.

3.Classification by Product Cross-section

Extrusion can also be classified by the cross-section of the product, such as pipes, profiles, and wire rods.

4.Classification by Extrusion Temperature

Extrusion can be classified into hot extrusion, warm extrusion, and cold extrusion. In the metallurgical industry, hot extrusion is mainly used, while in the mechanical industry, cold extrusion is the primary method.