Application of Volatile Stamping Oil in the Production of Automotive Seat Components

In the production process of automotive seat components, galvanized sheets are typically processed into discs through a wide-board circular punch press and then further shaped into finished products through a series of stamping processes.During stamping, lubrication is required for the shear surface to protect the molds. The appropriate oil is selected based on factors such as product thickness, precision requirements, and rust prevention periods.

1.Principle of Blanking and Forming

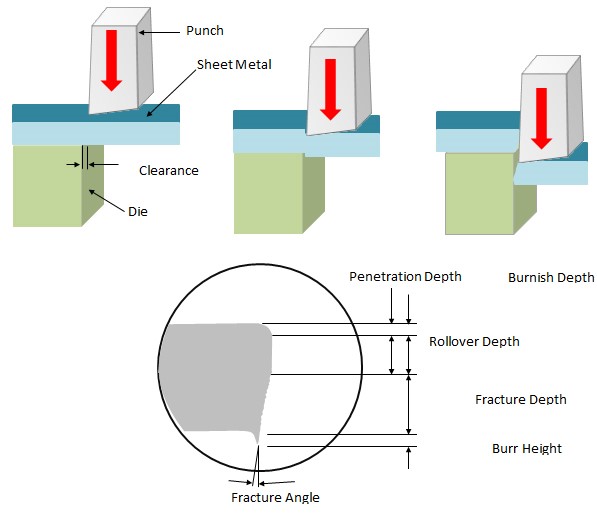

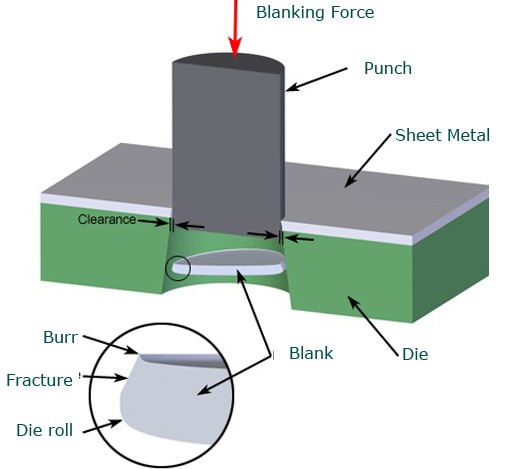

Blanking, also known as shearing, is a machining process where a workpiece is separated by two opposing blanking dies. The process can be divided into two types: open separation along an open contour curve (open separation) and closed separation along a closed contour curve (closed separation).

|

Shering the Sheet Metals |

Blanking Process of Sheet Metal |

|---|---|

|

|

|

During rough blanking, only 35%-70% of the metal thickness is sheared, and due to metal flow, the remaining edges are torn apart. The cut edges of the blanking piece are much smoother than the torn edges.

2.Application Case

A client produces automotive seat components using galvanized sheets with a thickness of 4.0-6.0mm and has been using rust-preventive blanking oil. The client’s rust prevention requirements between processes are minimal, but their downstream manufacturers lack cleaning lines, making it difficult to remove residual oil from the components. Therefore, they require a product that can be used without cleaning.

|

Blanking Equipment |

|---|

|

|

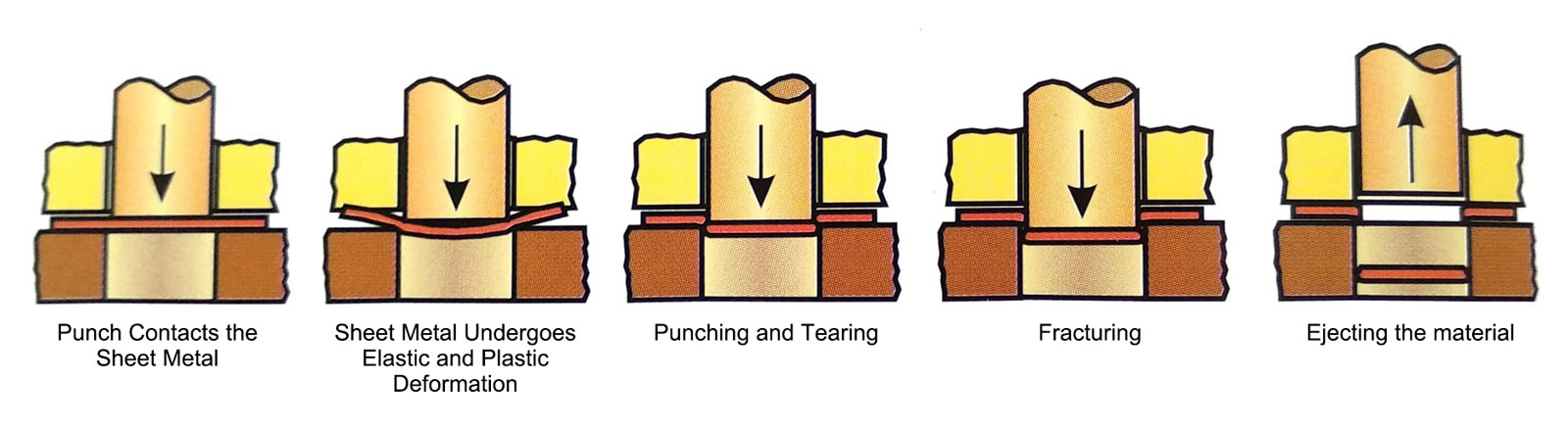

3.Production and Lubrication Process

|

Illustration of the Stages of Blanking and Forming |

|---|

|

|

After the raw material enters the stamping machine, stamping oil is sprayed, and then the stamping process is carried out.

|

Raw Material |

Stamped Product |

Product Details |

|---|---|---|

|

|

|

|

4.Issues Encountered

- The rust-preventive blanking oil has insufficient volatility, requiring subsequent cleaning processes, which some downstream customers cannot manage.

- The rust-preventive blanking oil has limited cooling performance, causing the temperature of the continuous stamping molds to be too high.

5.Solution

Given the client's need for short-term rust prevention and high requirements for no-clean applications, we provided a volatile stamping oil. This product ensures lubrication while offering adequate volatility and rust prevention.

6.Results

The product meets the lubrication requirements of continuous stamping. Customers reported satisfactory cooling effects during continuous production, and downstream customers no longer require a cleaning process.