Application of Drawing Oil in the Production of Bearing Housings

Bearing housings are widely used in equipment across industries such as steel, cement, mining, power plants, and ports. To ensure the bearings inside achieve maximum service life, manufacturing high-precision bearing housings is crucial. In the client’s production process, the bearing housings undergo five drawing stages, including a thinning draw during the shaping process, which places high demands on the lubricating oil. The product must be free of draw marks, and the tolerance dimensions must be strictly controlled within 0.2 mm.

1.Customer Overview

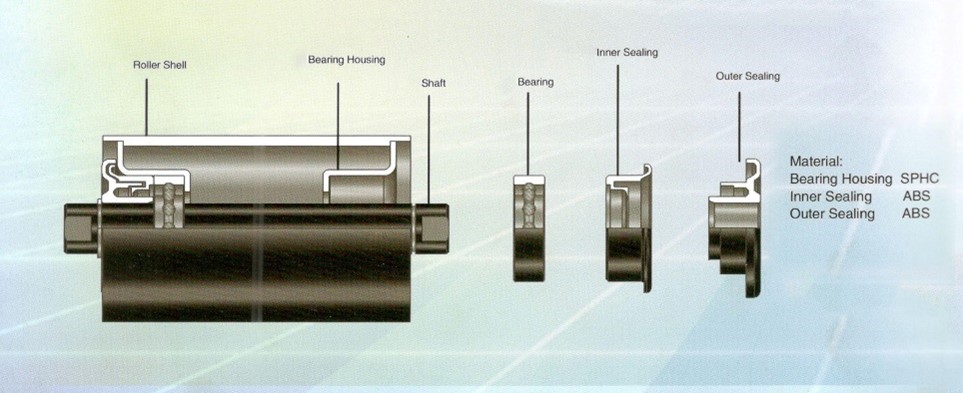

The client primarily produces precision stamped bearing housings for belt conveyor rollers, including models like TK, TK II, TK III, and DT II.

- Materials: Steel (SPHC), carbon steel

- Material Thickness: 2.5 mm to 6 mm

Bearing housings are widely used in equipment in the steel, cement, mining, power plant, and port industries. The tolerance dimensions must be extremely tight to ensure smooth operation of the bearings during use.

|

Example of Bearing Housing Structure |

Products |

|---|---|

|

|

|

2.Production and Lubrication Process

Roller Bearing Seat Production Process

|

Blanking |

First Extend |

Second Extend |

Third Extend |

Fourth Extend |

Reshaping |

Scrap Edge and Punching The Hole |

Packing |

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

In the production process, carbon steel sheets are passed through stamping equipment and undergo five drawing operations to produce the final product. The steps are as follows:

- First Extend

- Second Extend

- Third Extend

- Fourth Extend

- Shaping (Thinning Draw)

- Trimming and Punching

- Final Product

Drawing oil is mainly applied during the blanking, quaternary drawing, and shaping stages.

|

Stamping Equipment |

Precision Testing Instruments |

|---|---|

|

|

|

|

Mold |

Semi-manufactured |

Finished Products |

|---|---|---|

|

|

|

|

3.Existing Issues

- Some oils have insufficient lubricating performance, causing damage to the mold.

- Insufficient lubrication during the shaping process can lead to draw marks on the inner surface of the bearing housings, affecting product precision.

- Some oils lack adequate rust prevention properties, failing to meet mid-term rust protection requirements during maritime transportation.

Given the client's specific circumstances, we recommend using Comax's medium-load drawing oil, Form DP 60.

4.Solution

Based on the client's situation, the insufficient drawing is mainly due to inadequate lubrication performance. Therefore, we recommend the Form DP 60 drawing oil for the client.

5.Results

- During mass production, no significant draw marks appeared on the bearing housings.

- The mold replacement cycle remained normal, with the surface coating intact.

- Dimensional tolerances were maintained within 0.2 mm, as verified by checks on every 200 products.

Form DP 60 drawing oil can meet the lubrication and rust prevention needs of carbon steel sheets with thicknesses ranging from 2.5 mm to 6.0 mm during multi-stage cold extrusion processing.