Application of Forming and Drawing Oil in the Production of Drum Closures and Flanges

In the drum manufacturing process, the forming of closures involves operations such as stamping, turning, tapping or threading, welding, and galvanizing. The production process for flanges follows the sequence: blanking and drawing → secondary drawing → shaping and stamping → trimming → turning and boring → tapping. During the drawing process of closure flanges, drawing and forming oil is required for lubrication.

1.Customer Overview

The customer primarily produces embedded closure flanges for closed steel drums, available in two standard types: Type A and Type B.

|

Standard Type A Closer Flange |

Standard Type B Closer Flange |

|---|---|

|

|

|

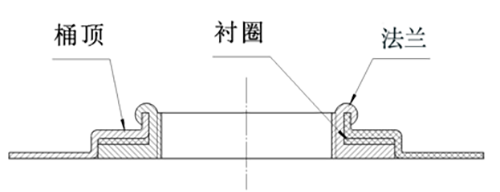

The flanges are ultimately installed onto the drum top and, together with the drum plug, gasket, liner, cap, and cap sealant, they ensure the drum’s sealing performance.

|

Flange and Barrel Top Locking Construction |

|---|

|

|

2.Production Process

The production process for flanges includes: blanking and drawing → secondary drawing → shaping and stamping → trimming → turning and boring → tapping. The blanking, secondary drawing, shaping, stamping, and trimming steps are all completed using a punch press. The flange material is carbon steel, which requires oil lubrication before being stamped and drawn into the final product.

|

Raw Materials |

Finished Product |

|---|---|

|

|

|

Production Process

3.Problems Encountered

Insufficient lubrication of the oil led to inadequate drawing, causing the flange depth to fall short of the required standard.

|

Previously Used Oils |

Qualified Products |

Unqualified Products |

|---|---|---|

|

|

|

|

Size Requirements

|

Code Name |

TM60 |

TM27 |

|

|---|---|---|---|

|

Outer Diameter |

D |

>63.5 |

30 |

|

Enlarged Hole Diameter |

d |

61.5 |

28.2 |

|

Enlarged Hole Depth |

h |

8 |

7 |

|

Distance Between Opposite Sides |

E |

75 |

40.5 |

|

External Height |

H |

18 |

16.5 |

|

Plate Thickness |

δ |

3 |

3 |

4.Solution

Based on the customer’s situation, the inadequate drawing was primarily due to the insufficient lubrication performance of the oil. Therefore, it was recommended that the customer use Form DP 60 drawing and forming oil.

5.Results

The production of closure flanges proceeded smoothly, fully meeting the lubrication requirements.