Application of Release Agents in the Aluminum Alloy Extrusion Industry

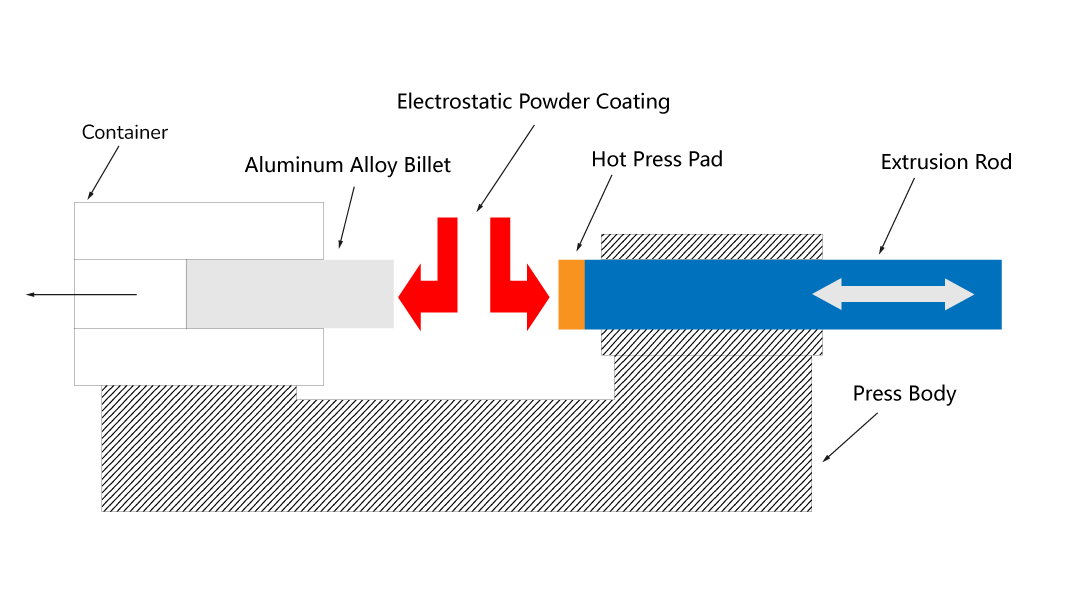

In typical aluminum product extrusion production, cylindrical aluminum billets are preheated to around 450-500°C and then extruded through a steel die using an extrusion pad. However, when the temperature exceeds 450°C, aluminum tends to adhere to steel, making billet adhesion to the extrusion pad a common challenge in the extrusion process. This issue can lead to the extrusion pad sealing the extrusion barrel, thereby affecting production.

To prevent billet adhesion to the extrusion pad, which can cause bubbles and surface irregularities on the aluminum profile, resulting in defective products, it is essential to ensure that the extrusion pad and billet separate quickly at the end of each extrusion cycle. Regular application of release oil on the extrusion pad is crucial to facilitate easy separation.

1.Customer Concerns: Poor Performance of Talc Powder as a Release Agent

The customer primarily manufactures aluminum profiles and needs to regularly apply a release agent on the extrusion machine to prevent aluminum products from sticking to the extrusion pad and barrel. The customer has been using talc powder, which, while inexpensive, does not provide satisfactory release performance.

2.Common Types of Release Agents

- Industrial Salt

- Talc Powder

- Acetylene

- Petroleum/Graphite Suspensions

- Boron Nitride

Each release agent has its own advantages and disadvantages:

- Industrial salt is low-cost but not environmentally friendly, and its release performance is subpar.

- Talc powder needs to be applied when the billet is in a cooled state, requiring cold sawing of the billet, which is not suitable for hot cutting methods, and the release performance is average.

- The carbon black generated by an acetylene flame is an excellent release agent, but it is carcinogenic, requiring special safety procedures for handling and cleaning. Acetylene is also flammable, necessitating precautions during storage and handling. Additionally, it can leave black marks on the profile, which may interact with anodization processes.

- Graphite suspensions can cause contamination and need to be reapplied after each extrusion cycle. They are also flammable at high temperatures, leading to bubbles and voids in the aluminum profile. Furthermore, graphite-based lubricants can cause electrical equipment short circuits.

- Boron nitride offers better release performance than graphite and acetylene but is more expensive.

|

Release Agent Application Point |

|---|

|

|

3.Extrusion Process

The use of lubricants can often lead to product surface contamination, and the lubricant may flow into the product's core, causing "extrusion tail defects." Therefore, in the extrusion of aluminum and aluminum alloy billets, "non-lubricated extrusion" is generally employed, meaning no lubricant is applied to the extrusion barrel walls, and release agents are only applied to the extrusion pad to facilitate demolding.

Principles of the Extrusion

Extrusion Equipment and Tools

|

Extrusion Production Line |

Billet |

After Cold Sawing the Billet, Apply Talc Powder and Dry |

|---|---|---|

|

|

|

|

|

Horizontal Extrusion Press |

Extrusion Die |

Exit Cooling Device |

|---|---|---|

|

|

|

|

Relevant Parameters

|

Extrusion Press |

Billet Material |

Billet Diameter |

Billet Length |

|---|---|---|---|

|

4000-Ton Horizontal Extrusion Press |

Aluminum Alloy |

27.5cm |

86cm |

|

EXTRUSION RATIO |

EXTRUSION METHOD |

HEATING FURNACE |

HEATING TEMPERATURE |

|

≈230 |

Direct Extrusion |

Gas Furnace, Electric Furnace |

Aluminum Billet: 460 - 500℃ Extrusion Barrel: 400 - 430℃ Extrusion Die: 430 - 460℃ |

|

EXTRUSION PAD |

EXTRUSION DIE |

EXTRUSION SPEED |

EXIT SPEED |

|

Fixed Extrusion Pad |

Flat Die, Combination Die |

1.8mm/s |

0.8mm/s |

4.Existing Problems

- Using talc powder as a release agent requires application when the billet is in a cooled state, which necessitates prior cold sawing. Compared to hot cutting, cold sawing results in higher metal loss and lower production efficiency.

- Talc powder provides only average release performance, and occasional aluminum adhesion still occurs.

Adhesion Phenomenon

|

Aluminum Sticking to the Extrusion Pad |

Aluminum Sticking During Scrap Separation |

|---|---|

|

|

|

5.Solution

Graphite-based release agents can meet the requirements for non-stick release. For higher quality demands and extended extrusion pad lifespan, boron nitride-based release agents are recommended.

|

Release Agent Application Point |

Smooth Scrap Separation |

|---|---|

|

|

|