Water-Soluble/Volatile Pipe Bending Lubricants in Copper Tube Bending Applications

Compared to stainless steel tubes, copper and aluminum tubes are more prone to deformation during bending. Therefore, their lubrication requirements are relatively low, but their cleanliness requirements are much stricter. In air conditioning refrigeration systems, which typically use copper tubes, high cleanliness standards are essential. If the pipes are clogged with oil residues or welding debris, it will directly affect the cooling performance of the air conditioner.

1.Customer Concerns: Insufficient cleaning performance of bending oil, making it difficult to clean air conditioning pipes.

The client manufactures air conditioning system pipes and refrigeration components for manufacturers such as York, Midea, and Gree. The traditional tube bending lubricant poses difficulties in the subsequent cleaning process. If the cleaning is not thorough, the products will fail quality inspection, leading to returns and rework.

|

Products |

|---|

|

|

2.Production Process and Principle

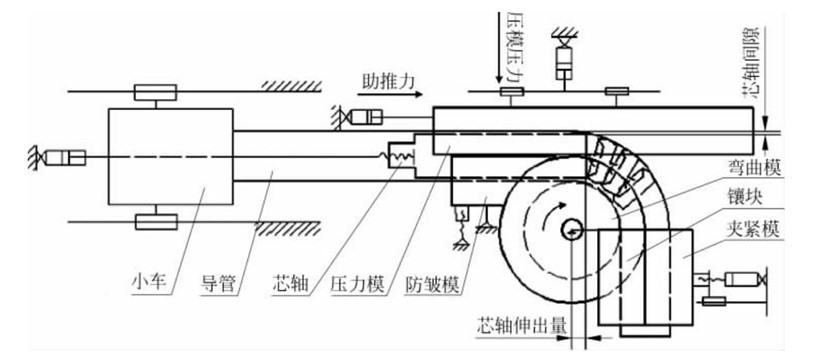

Metal tubes are bent and shaped according to set parameters using CNC pipe bending machines.

|

CNC Pipe Bending Machine Structure Diagram |

Lubrication Point - Single-Segment Flexible Mandrel |

|---|---|

|

|

|

Small-Diameter Pipe Bending Process

Large-Diameter Pipe Bending Process

3.Problems

After bending, the finished product undergoes 11 processing steps, including pickling, washing, brightening, cleaning, passivation, and air blowing. The previously used bending oil required soaking for 40-45 seconds during the pickling step, and even then, thorough cleaning was not always achieved.

4.Solution

- For small-diameter copper tubes, where lubrication requirements are low, volatile bending oil is recommended to eliminate the need for subsequent cleaning.

- For large-diameter copper tubes, where some lubrication is needed, water-soluble copper/aluminum tube bending lubricants are recommended, facilitating easier cleaning in subsequent processes.

5.Results

After switching to the recommended products, the lubrication needs during tube bending were met, and the cleaning process was significantly improved. The pickling soak time was reduced to 10-15 seconds, greatly saving production time for customers.